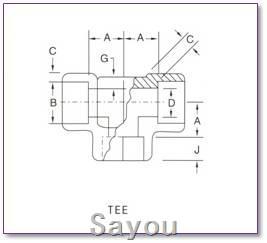

FORGED TEE AND CROSS

A) Types: Socket Weld- Tee, Socket Weld- Cross (Straight type and Reducing Type)

B) Pressure Ratings: 1500LB, 2000LB, 3000LB, 6000LB, 9000LB

C) Size: 1/8"~4" (DN6 ~ DN100)

D) Standard: ASME B16.11

E) Material Specification:

ASTM A 105, ASTM A 181, ASTM A 350, ASTM A 516, ASTM A 694, ASTM A 36

ASTM A182 F304/F304L, F316/F316L, 309, 310, 317L, 321, 347, 904L

Aluminum 3003, 6061; HASTALLOY B-2, C-276, G, X, C-22

INCONEL 600, 601, 625, 718; INCOLLOY 800, 825, 800H, 800HT

MONEL 400; COPPER C70600, C71500; DUPLEX F51, F53; TITANIUM Gr2, Gr12

Dimensions in Millimeters

| DN | Nom.Pipe Size | Socket Bore Dia.(2) B | Bore Diameter of Fittings(2) D | Socket Wall Thickness(1) C | Body Wall Thickness G | Depth of Socket Min. J | |||||||||

| Class Designation | Class Designation | ||||||||||||||

| Class Designation | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||||

| 3000 | 6000 | 9000 | Ave. | Min. | Ave. | Min. | Ave. | Min. | Min. | Min. | Min. | ||||

| 6 | 1/8 | 11.2 | 7.6 | 4.8 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 | ||||

| 10.8 | 6.1 | 3.2 | |||||||||||||

| 8 | 1/4 | 14.6 | 10.0 | 7.1 | 3.78 | 3.30 | 4.60 | 4.01 | 3.02 | 3.68 | 9.5 | ||||

| 14.2 | 8.5 | 5.6 | |||||||||||||

| 10 | 3/8 | 18.0 | 13.3 | 9.9 | 4.01 | 3.50 | 5.03 | 4.37 | 3.20 | 4.01 | 9.5 | ||||

| 17.6 | 11.8 | 8.4 | |||||||||||||

| 15 | 1/2 | 22.2 | 16.6 | 12.5 | 7.2 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 |

| 21.8 | 15.0 | 11.0 | 5.6 | ||||||||||||

| 20 | 3/4 | 27.6 | 21.7 | 16.3 | 11.8 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 |

| 27.2 | 20.2 | 14.8 | 10.3 | ||||||||||||

| 25 | 1 | 34.3 | 27.4 | 21.5 | 16.0 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 |

| 33.9 | 25.9 | 19.9 | 14.4 | ||||||||||||

| 32 | 1-1/4 | 43.1 | 35.8 | 30.2 | 23.5 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 |

| 42.7 | 34.3 | 28.7 | 22.0 | ||||||||||||

| 40 | 1-1/2 | 49.2 | 41.6 | 34.7 | 28.7 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 |

| 48.8 | 40.1 | 33.2 | 27.2 | ||||||||||||

| 50 | 2 | 61.7 | 53.3 | 43.6 | 38.9 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 |

| 61.2 | 51.7 | 42.1 | 37.4 | ||||||||||||

| 65 | 2-1/2 | 74.4 | 64.2 | 8.76 | 7.67 | 7.01 | 16.0 | ||||||||

| 73.9 | 61.2 | ||||||||||||||

| 80 | 3 | 90.3 | 79.4 | 9.52 | 8.30 | 7.62 | 16.0 | ||||||||

| 89.8 | 76.4 | ||||||||||||||

| 100 | 4 | 115.7 | 103.8 | 10.69 | 9.35 | 8.56 | 16.0 | ||||||||

| 115.2 | 100.7 | ||||||||||||||

| DN | Nom Pipe Size | Center to Bottom of Socket-A | Laying Lengths | Tolerances± | End Wall Thickness K Min | ||||||||||

90º Elbows Tees,Crosses | 45ºElbows | Couplings E | Half Couplings F | A | E | F | |||||||||

| Class Designation | Class Designation | Class Designation | |||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||

| 6 | 1/8 | 11.0 | 11.0 | 8.0 | 8.0 | 6.5 | 16.0 | 1.0 | 1.5 | 1.0 | 4.8 | 6.4 | |||

| 8 | 1/4 | 11.0 | 13.5 | 8.0 | 8.0 | 6.5 | 16.0 | 1.0 | 1.5 | 1.0 | 4.8 | 6.4 | |||

| 10 | 3/8 | 13.5 | 15.5 | 8.0 | 11.0 | 6.5 | 17.5 | 1.5 | 3.0 | 1.5 | 4.8 | 6.4 | |||

| 15 | 1/2 | 15.5 | 19.0 | 25.5 | 11.0 | 12.5 | 15.5 | 9.5 | 22.5 | 1.5 | 3.0 | 1.5 | 6.4 | 7.9 | 11.2 |

| 20 | 3/4 | 19.0 | 22.5 | 28.5 | 13.0 | 14.0 | 19.0 | 9.5 | 24.0 | 1.5 | 3.0 | 1.5 | 6.4 | 7.9 | 12.7 |

| 25 | 1 | 22.5 | 27.0 | 32.0 | 14.0 | 17.5 | 20.5 | 12.5 | 28.5 | 2.0 | 4.0 | 2.0 | 9.6 | 11.2 | 14.2 |

| 32 | 1-1/4 | 27.0 | 32.0 | 35.0 | 17.5 | 20.5 | 22.5 | 12.5 | 30.0 | 2.0 | 4.0 | 2.0 | 9.6 | 11.2 | 14.2 |

| 40 | 1-1/2 | 32.0 | 38.0 | 38.0 | 20.5 | 25.5 | 25.5 | 12.5 | 32.0 | 2.0 | 4.0 | 2.0 | 11.2 | 12.7 | 15.7 |

| 50 | 2 | 38.0 | 41.0 | 54.0 | 25.5 | 28.5 | 28.5 | 19.0 | 41.0 | 2.0 | 4.0 | 2.0 | 12.7 | 15.7 | 19.0 |

| 65 | 2-1/2 | 41.0 | 28.5 | 19.0 | 43.0 | 2.5 | 5.0 | 2.5 | 15.7 | 19.0 | |||||

| 80 | 3 | 57.0 | 32.0 | 19.0 | 44.5 | 2.5 | 5.0 | 2.5 | 19.0 | 22.4 | |||||

| 100 | 4 | 66.5 | 41.0 | 19.0 | 48.0 | 2.5 | 5.0 | 2.5 | 22.4 | 28.4 | |||||

NOTES:

(1)Average of Socket Wall Thickness around periphery shall be no less than listed values

The minimun values are permitted in localized areas.

(2)Upper and lower values for each size are the respective maximum and minimum dimensions.

PREV:FORGED ELBOW

NEXT:FORGED NIPPLE

{{ title }}

{{ description }}